Ever had a flat soda pop? Soda fizzes because it’s pumped full of carbon gas at pressures of up to 1,200 pounds per square inch. It goes flat because Mother Nature has designed things so the pressure of gas inside water eventually adjusts to equal the pressure of gas outside. But how does that affect your boiler?

Boiler Basics

A boiler uses tubes to heat water containing undissolved gases, including oxygen and carbon dioxide. When the heated water changes to steam, the gases dissolve and permeate the air inside the boiler. That’s when the trouble begins.

Undissolved Gases and Boiler Damage

Undissolved oxygen corrodes a boiler’s tube-metal surfaces, covering them with tiny “blisters.” Small holes under the blisters eventually eat through the metal, resulting in leaks. Unless the dissolved oxygen is eliminated, the boiler will be useless in within a few months.

Undissolved carbon dioxide acidifies boiler water, causing a buildup of highly corrosive carbonic acid. It threatens the entire boiler system. Even worse, dissolved oxygen water makes the carbonic acid 40 percent more corrosive. So how can you combat this corrosive gas duo?

Spray Them Away

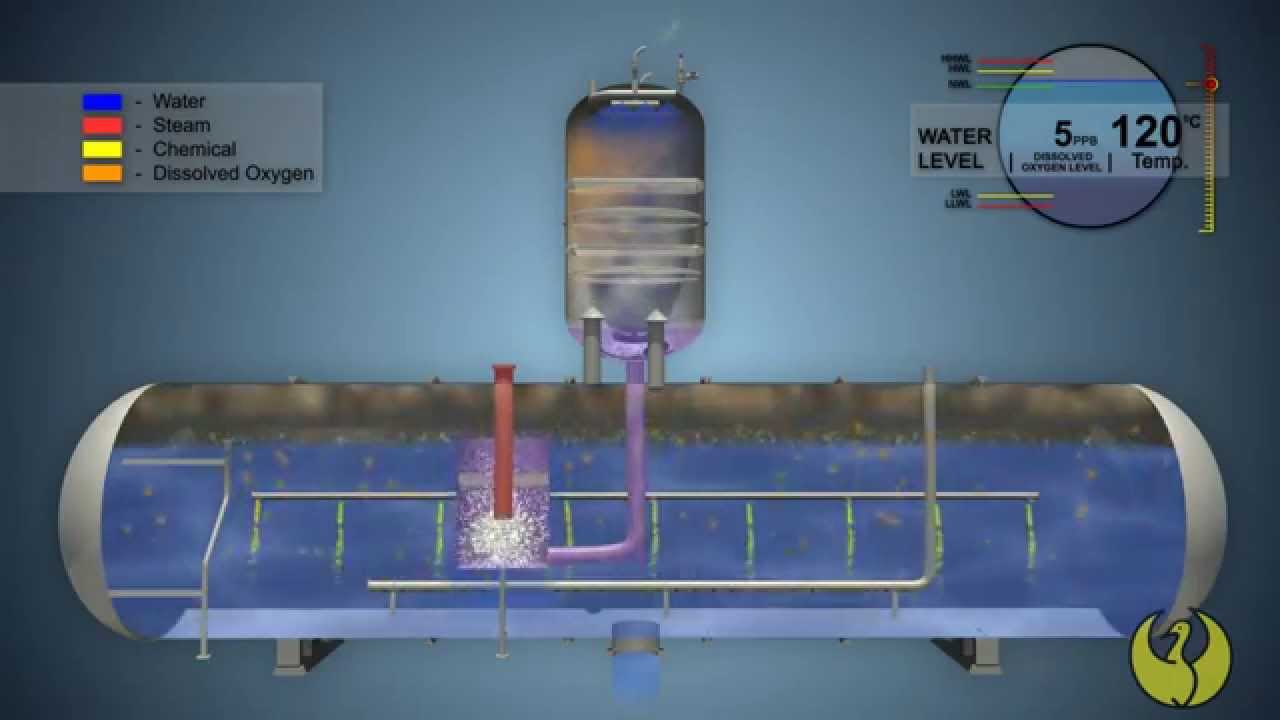

Because its molecules stick together so tightly, water has a very high surface tension. In other words, it doesn’t like to let go of the undissolved gases inside. That’s where a good spray deaerator comes in. The boiler’s unaerated feedwater passes through the deaerator’s stainless-steel spray valves and forms a very fine spray.

As it’s exposed to steam, the spray releases most of its corrosive gases. Then it’s funneled down through a second chamber with even hotter, cleaner steam where residual gases are dissolved. The deaerator vents to released gases into the atmosphere and returns the gas-free water to the boiler’s storage area.

Replacing a commercial boiler can be prohibitively expensive. Equipping yours with a spray deaerator to extend its life and reduce its operating costs can pay off in a big way!