Daegu Gyeongbuk Institute of Science & Expertise (DGIST, President Yang Kook) Professor Hongsoo Choi’s staff of the Division of Robotics and Mechatronics Engineering collaborated with Professor Sung-Received Kim’s staff at Seoul St. Mary’s Hospital, Catholic College of Korea, and Professor Bradley J. Nelson’s staff at ETH Zurich to develop a know-how that produces greater than 100 microrobots per minute that may be disintegrated within the physique.

Microrobots aiming at minimally invasive focused precision remedy may be manufactured in varied methods. Amongst them, ultra-fine 3D printing know-how known as two-photon polymerization technique, a way that triggers polymerization by intersecting two lasers in artificial resin, is probably the most used. This know-how can produce a construction with nanometer-level precision. Nonetheless, a drawback exists in that producing one microrobot is time consuming as a result of voxels, the pixels realized by 3D printing, have to be cured successively. As well as, the magnetic nanoparticles contained within the robotic can block the sunshine path throughout the two-photon polymerization course of. This course of consequence is probably not uniform when utilizing magnetic nanoparticles with excessive focus.

To beat the restrictions of the prevailing microrobot manufacturing technique, DGIST Professor Hongsoo Choi’s analysis staff developed a way to create microrobots at a excessive velocity of 100 per minute by flowing a mix of magnetic nanoparticles and gelatin methacrylate, which is biodegradable and may be cured by gentle, into the microfluidic chip. That is greater than 10,000 instances sooner than utilizing the prevailing two-photon polymerization technique to fabricate microrobots.

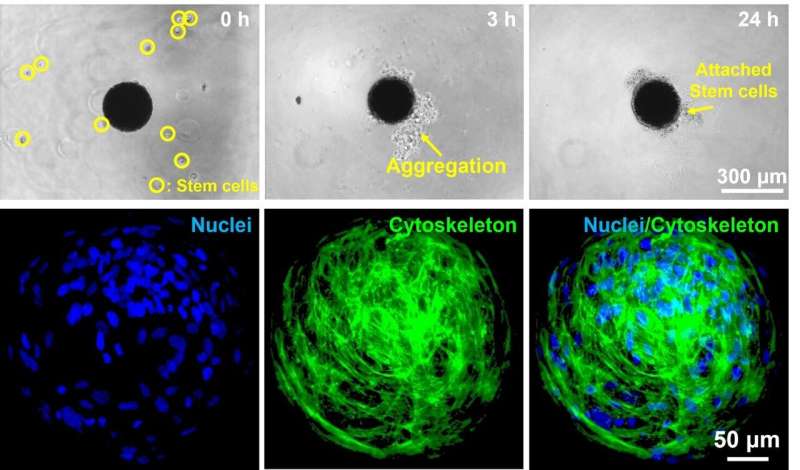

Then, the microrobot produced with this know-how was cultured with human nasal turbinated stem cells collected from human nostril to induce stem cell adherence to the floor of the microrobot. Via this course of, a stem cell carrying microrobot, together with magnetic nanoparticles inside and stem cells hooked up to the outside floor, was fabricated. The robotic strikes because the magnetic nanoparticles contained in the robotic responds to an exterior magnetic subject and may be moved to a desired place.

Selective cell supply was tough within the case of the prevailing stem cell remedy. Nonetheless, the stem cell carrying microrobot can transfer to a desired location by controlling the magnetic subject generated from the electromagnetic subject management system in actual time. The analysis staff carried out an experiment to look at whether or not the stem cell carrying microrobot may attain the goal level by passing by means of a maze-shaped microchannel, and accordingly confirmed that the robotic may transfer to the specified location.

As well as, the degradability of the microrobot was evaluated by incubating the stem cell carrying microrobot with degrading enzyme. After 6 hours of incubation, the microrobot was fully disintegrated, and the magnetic nanoparticles contained in the robotic had been collected by the magnetic subject generated from the magnetic subject management system. Stem cells had been proliferated on the location the place the microrobot was disintegrated. Subsequently, the stem cells had been induced to distinguish into nerve cells to verify regular differentiation; the stem cells had been differentiated into nerve cells after roughly 21 days. This experiment verified that delivering stem cells to a desired location utilizing a microrobot was doable and that the delivered stem cells may function a focused precision therapeutic agent by exhibiting proliferation and differentiation.

Moreover, the analysis staff confirmed whether or not the stem cells delivered by the microrobot exhibited regular electrical and physiological traits. The ultimate aim of this examine is to make sure that the stem cells delivered by the robotic usually carry out their bridge function in a state the place the connection between the prevailing nerve cells is disconnected. To verify this, hippocampal neurons extracted from rat embryo that stably emit electrical indicators had been utilized. The corresponding cell was hooked up to the floor of the microrobot, cultured on a micro-sized electrode chip, and electrical indicators had been noticed from the hippocampal neurons after 28 days. Via this, the microrobot was verified to correctly carry out its function as a cell supply platform.

DGIST Professor Hongsoo Choi mentioned, “We anticipate that the applied sciences developed by means of this examine, reminiscent of mass manufacturing of microrobots, exact operation by electromagnetic fields, and stem cell supply and differentiation, will dramatically improve the effectivity of focused precision remedy sooner or later. ”

In the meantime, the outcomes of this examine had been printed on June 23 within the scientific journal Small .

Microrobots for treating neurological ailments by means of intra-nasal administration

Seungmin Noh et al, A Biodegradable Magnetic Microrobot Based mostly on Gelatin Methacrylate for Exact Supply of Stem Cells with Mass Manufacturing Functionality, Small (2022). DOI: 10.1002/smll.202107888

Small

Offered by DGIST (Daegu Gyeongbuk Institute of Science and Expertise)

Quotation: Expertise produces greater than 100 medical microrobots per minute that may be disintegrated within the physique (2022, September 27) retrieved 3 October 2022 from https://phys.org/information/2022-09-technology-medical-microrobots-minute- disintegrated.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no half could also be reproduced with out the written permission. The content material is supplied for data functions solely.